Text excerpts and images obtained from A. Zahner Company, and full research findings published on company website,

LEAN MANUFACTURING OF CUSTOM PARTS

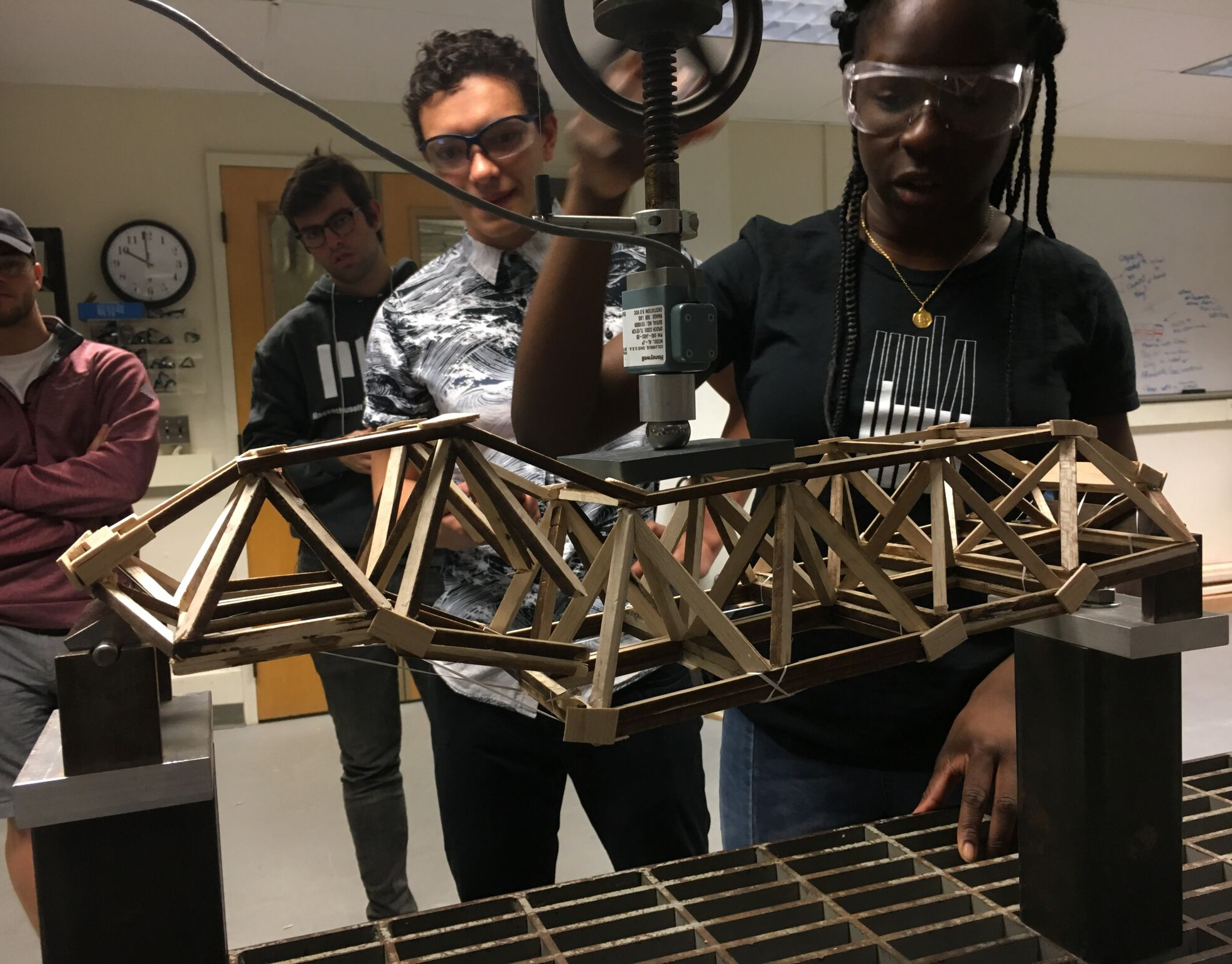

"Intern Michelle A. Menkiti, an architecture undergraduate student at the Massachusetts Institute of Technology, joined the team for 10 weeks to delve into and investigate how metals and materials move around the Zahner facilities. With Zahner’s continually expanding work portfolio, and a finite amount of production space, Menkiti’s challenge was to observe current storage and movement methods and then explore ways of improving them. Throughout the summer, Menkiti’s main case study was a 1M+ sqft project in active production- the main question posed to Menkiti was- Where is everything?

At any one point in time Zahner is actively producing 50-80 architectural projects, often composed of tens of thousands of unique parts. Michelle’s project ‘Moving Metal’ targeted the visualization of these shifting entities as both raw goods and finished parts...

...The tools created for the Moving Metal project helped to improve transparency between Zahner departments, making Zahner more efficient and competitive. Future work will build on Michelle’s proof of concept tools to be utilized by the larger engineering teams."

Inventory Visualization Tool Linked to Zahner Database